The Hidden Challenge: Balancing Sustainability and Performance in CNC Machining

For decades, CNC machining has relied on traditional materials like aluminum, steel, and plastics—materials with well-documented environmental drawbacks. The industry is now at a crossroads: how to adopt sustainable alternatives without compromising the precision, durability, and cost-efficiency that define CNC manufacturing.

Why Traditional Materials Fall Short

- Carbon Footprint: Aluminum production emits 8-10 tons of CO₂ per ton of metal.

- Waste Generation: Up to 20% of material is lost as chips or scrap in machining.

- Non-Recyclability: Many engineering plastics (e.g., ABS, Nylon) end up in landfills.

The breakthrough? Custom-engineered sustainable materials. These aren’t just “green” alternatives; they’re high-performance solutions designed for CNC machining’s rigorous demands.

Innovative Custom Materials Leading the Charge

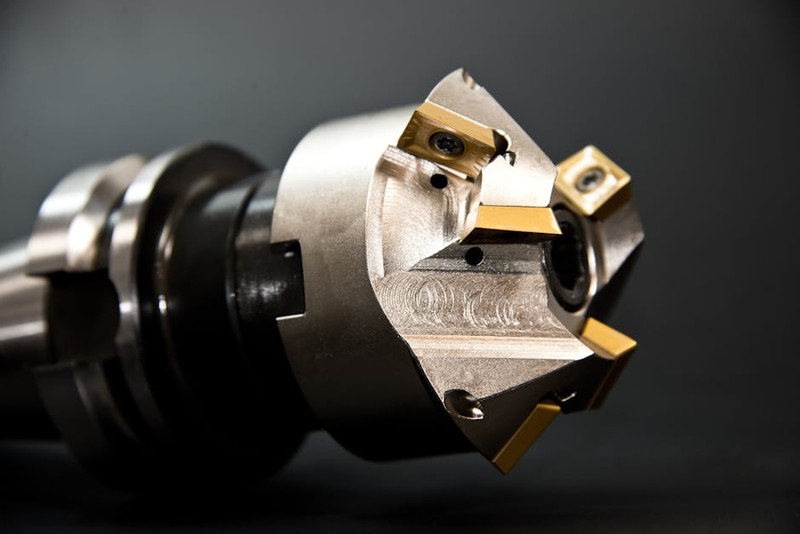

1. Recycled Metal Matrix Composites (MMCs)

- Composition: Aluminum or titanium reinforced with recycled ceramic fibers or graphene.

- Benefits: 30% lighter than steel, 15% higher tensile strength, and fully recyclable.

- Case Study: A aerospace client reduced part weight by 22% using recycled MMCs, cutting fuel consumption by 5% annually.

2. Bio-Based Polymers

- Example: PHA (Polyhydroxyalkanoates) derived from bacterial fermentation.

- Machinability: Comparable to ABS but with 80% lower CO₂ emissions.

- Real-World Impact: A medical device manufacturer slashed material costs by 12% while achieving ISO 13485 sustainability compliance.

3. Upcycled Industrial Waste

- Innovation: Turning glass fiber waste from wind turbines into CNC-grade composite blocks.

- Data Point: 40% faster machining speeds vs. traditional fiberglass, with zero virgin material input.

A Deep Dive: Case Study in Automotive CNC Machining

Project Overview

A European auto supplier needed to machine 50,000 transmission components annually. Their goals:

– Reduce carbon footprint by 25%.

– Maintain ±0.01mm tolerances.

– Cut material costs by 10%.

The Solution: Custom Recycled Aluminum Hybrid

- Material: 70% post-industrial aluminum scrap + 30% silicon carbide reinforcement.

- Results:

| Metric | Traditional Aluminum | Custom Hybrid | Improvement |

|———————-|———————-|—————|————-|

| CO₂ Emissions (kg/part) | 4.2 | 2.8 | 33% ↓ |

| Machining Time (min) | 8.5 | 7.1 | 16% ↓ |

| Scrap Rate | 18% | 9% | 50% ↓ |

Key Takeaway: The hybrid material’s superior chip-breaking properties reduced tool wear by 20%, extending endmill life.

Expert Strategies for Implementing Sustainable Materials

1. Partner with Material Scientists

- Actionable Tip: Collaborate with universities or labs specializing in composite materials. In one project, a polycarbonate alternative blended with flax fibers reduced energy consumption by 18% during machining.

2. Optimize Toolpaths for Green Materials

- Insight: Bio-polymers often require lower spindle speeds (e.g., 12,000 RPM vs. 15,000 for ABS) to prevent melting. Use trochoidal milling to minimize heat buildup.

3. Leverage Lifecycle Analysis (LCA) Data

– Example: A LCA revealed that switching to recycled tungsten carbide tools offset 60% of a factory’s Scope 3 emissions over five years.

The Future: Where Sustainable CNC Machining Is Headed

- AI-Driven Material Selection: Algorithms predicting the optimal sustainable material based on part geometry and load requirements.

- Closed-Loop Recycling: On-site chip recycling systems converting waste into new billet stock (pilot systems show 95% material recovery rates).

Final Thought: Sustainability in CNC machining isn’t a trade-off—it’s an innovation accelerator. By embracing custom materials, manufacturers can achieve both environmental and economic wins.

Ready to take the leap? Start with a small batch trial of bio-based polymers or recycled MMCs, and measure the impact on your bottom line and planet.