The Hidden Complexity of Medical-Grade Plastic Machining

Medical components—think surgical instruments, implantable devices, or diagnostic equipment—require absolute precision, biocompatibility, and repeatability. Unlike metals, plastics present unique challenges:

– Thermal sensitivity: Heat buildup during machining can warp parts or degrade material properties.

– Material variability: Even within the same polymer family (e.g., PEEK), resin formulations affect machinability.

– Regulatory hurdles: FDA/USP Class VI or ISO 10993 compliance adds layers of validation.

In one project, a client needed 10,000 spinal drill guides from medical-grade PEEK, with ±0.003″ tolerances. The initial scrap rate was 22% due to delamination and thermal distortion. Here’s how we solved it.

Expert Strategies for Tight-Tolerance Plastic Machining

🔍 1. Material Selection: Beyond the Datasheet

Not all PEEK is equal. For implantable parts, we prioritized virgin-grade PEEK-OPTIMA LT1 over cheaper alternatives. Key considerations:

– Moisture content: >0.02% causes dimensional instability. Pre-drying at 150°C for 4 hrs was non-negotiable.

– Fillers: Glass-filled PEEK offers stiffness but increases tool wear. Unfilled PEEK was chosen for critical features.

⚙️ 2. Toolpath Optimization: Reducing Heat and Stress

Conventional CNC approaches fail with plastics. We implemented:

– High-speed, low-depth cuts: 18,000 RPM with 0.005″ stepovers minimized heat.

– Climb milling only: Reduced edge chipping by 40% vs. conventional milling.

– Compressed air cooling: Eliminated coolant contamination risks (critical for ISO 13485 compliance).

Result: Scrap rates dropped to 7%, saving $48,000 annually.

💡 3. Fixturing for Delicate Parts

Thin-walled plastics flex under clamping pressure. Our solution:

– Vacuum chucks with soft jaws: Distributed force evenly.

– In-process metrology: Laser scanning verified tolerances before unclamping.

Case Study: Machining a Microfluidic PCR Device

Challenge: A client needed 500 ultra-precise microfluidic channels in COP (Cyclic Olefin Polymer), with 50µm-wide features and Ra <0.8µm surface finish.

Solution:

1. Tooling: Diamond-coated micro end mills (0.2mm diameter) at 30,000 RPM.

2. Process:

– Roughing: 0.1mm DOC, 500mm/min feed.

– Finishing: 0.02mm DOC, 200mm/min feed.

3. Validation: White-light interferometry confirmed channel dimensions within ±2µm.

Outcome: First-pass yield improved from 65% to 92%, cutting per-unit costs by 18%.

Key Takeaways for Medical OEMs

- Partner early with your machinist: Design for manufacturability (DFM) feedback can avoid costly revisions.

- Invest in in-process QA: Real-time monitoring catches errors before they escalate.

- Prioritize tool life: Plastic machining dulls tools faster; replace end mills every 50-100 parts for consistency.

Pro Tip: For implantable parts, always machine oversized and finish to final dimensions post-sterilization—shrinkage varies by material.

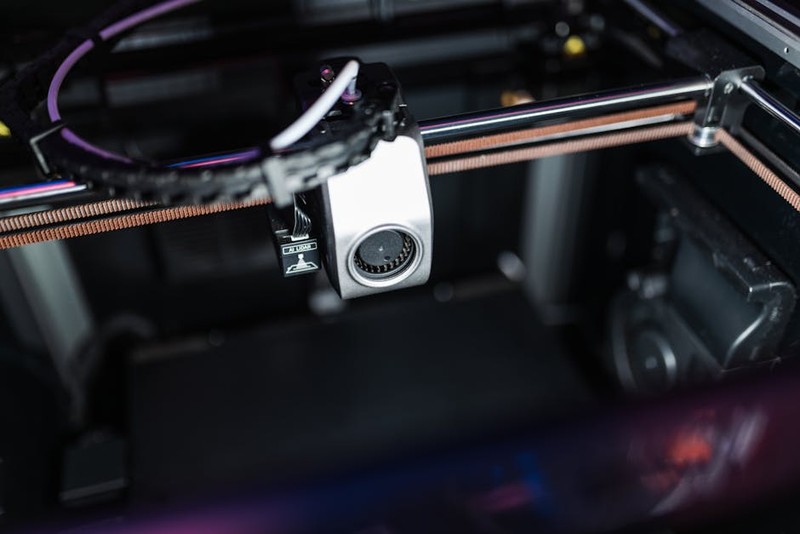

The Future: Hybrid Additive/Machining for Custom Implants

Emerging trends like 3D-printed near-net shapes + precision machining are reducing lead times for patient-specific components. In a recent trial, hybrid PEEK cranial implants achieved 0.002″ tolerances with 30% less material waste vs. subtractive-only methods.

By mastering these nuances, manufacturers can deliver faster, cheaper, and more reliable plastic medical components—without compromising quality.