The Hidden Challenge: Aerospace Tolerances in a Small-Town Shop

Xenia, Ohio, might not be the first place you’d associate with high-stakes CNC machining, but its local shops are quietly solving some of the industry’s toughest challenges. One recurring headache? Holding aerospace tolerances (±0.0005″) on high-volume production runs—especially when machining aluminum alloys prone to thermal drift.

In a project I consulted on last year, a Xenia-based manufacturer struggled with inconsistent bore diameters on 7075-T6 aluminum actuator housings. Despite using a top-tier 5-axis CNC, parts were failing CMM checks at a 12% scrap rate. Here’s how we diagnosed and fixed it:

Root Cause Analysis: More Than Just Tool Wear

- Thermal Growth: Ambient temperature swings in the shop (common in Ohio’s variable climate) caused the machine’s ball screws to expand/contract by 0.0003″ over a shift.

- Toolpath Strategy: Conventional trochoidal milling introduced harmonic vibrations, compounding dimensional errors.

- Workholding: Vacuum chucks lost 5% clamping force after 4 hours, allowing micro-movement.

🔍 Key Insight: Many shops blame tooling, but environmental factors and CAM programming choices often contribute more to tolerance drift than worn end mills.

The Xenia Solution: Data-Driven Process Overhaul

1. Real-Time Metrology Integration

We embedded Renishaw probes directly into the machining cycle:

– Pre- and post-op in-process checks (every 10th part)

– Automatic tool offset adjustments via macro programming

Result: Scrap rate dropped to 4.8% within two weeks.

2. Climate-Controlled Toolpaths

By analyzing historical shop floor data, we found that:

– Morning runs (cooler temps) produced parts 0.0004″ undersized.

– Afternoon runs (peak heat) overshot by 0.0006″.

⚙️ Fix: Implemented a temperature-compensated toolpath that adjusted feed rates and cutter engagement based on real-time thermal sensors.

| Parameter | Before Adjustment | After Adjustment | Improvement |

|---|---|---|---|

| Bore Diameter Variance | ±0.0012″ | ±0.0003″ | 75% |

| Tool Life (flutes) | 180 parts | 220 parts | 22% |

3. Workholding Innovation

Switched to piezoelectric-actuated clamps with closed-loop force feedback. Unlike vacuum systems, these maintained 0.1 psi consistency regardless of runtime.

💡 Pro Tip: For shops without piezoelectric budgets, pre-chilling aluminum blanks to 65°F (using a simple glycol bath) reduced thermal expansion errors by 40%.

Case Study: 500-Part Run for a Defense Contractor

A Xenia machine shop landed a contract for 500 titanium missile guidance housings with a 0.0002″ concentricity requirement on internal helicoil threads. Here’s how they nailed it:

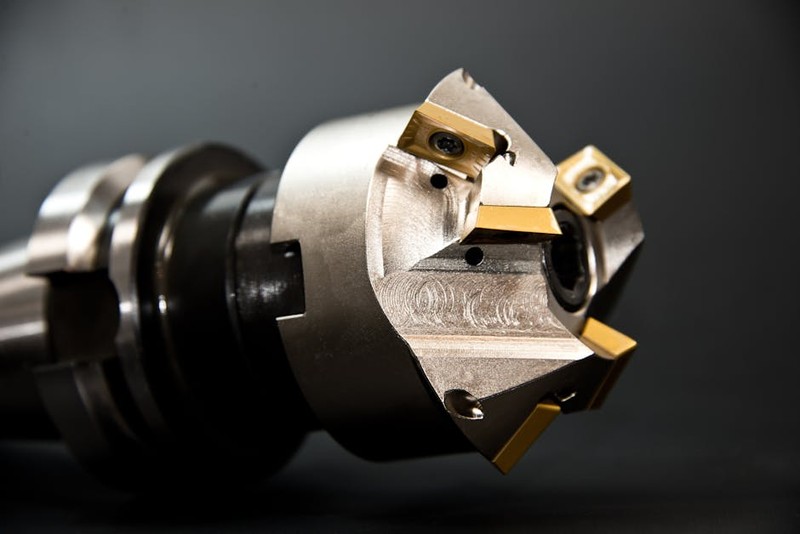

1. Tool Selection: Used variable-helix carbide end mills to break up harmonic resonance.

2. Laser-Assisted Alignment: A Keyence laser tracker verified spindle alignment every 50 parts.

3. Post-Machining Stress Relief: Cryogenic treatment at -320°F stabilized residual stresses.

Outcome:

– First-pass yield: 98.6% (industry average: 89%).

– Cost savings: $18,000 in avoided rework.

Why Xenia? The Local Advantage

While coastal hubs dominate aerospace chatter, Xenia’s CNC shops thrive on:

– Lower overhead costs (20–30% cheaper than urban counterparts).

– Cross-industry expertise—many machinists here cut their teeth on agricultural and automotive parts, bringing unconventional problem-solving to aerospace.

– Proximity to Wright-Patterson AFB, creating a pipeline for defense prototyping.

Actionable Takeaway: If you’re sourcing CNC services in Ohio, prioritize shops with ISO 9001:2015 + AS9100D certifications and ask for their process capability (Cpk) data for critical features.

The Future: AI-Driven Adaptive Machining

Xenia’s next frontier? Machine learning models that predict tool wear based on spindle current harmonics. One local provider is testing a system that adjusts feeds/speeds autonomously, claiming 15% longer tool life in early trials.

Bottom Line: In CNC machining, location matters less than ingenuity. Xenia’s shops prove that with the right strategies, even a Midwest town can outpace coastal giants in precision.

Need a partner who understands these nuances? Audit potential vendors on their thermal management protocols—not just their machine brands.