The Hidden Challenges of Local CNC Routing Services

Not all CNC routing providers are created equal. While searching for “CNC routing services near me,” you’ll encounter a wide range of options—from hobbyist shops to industrial-grade operations. The real challenge lies in identifying which partner can deliver precision, scalability, and cost-efficiency for your specific project.

Common Pitfalls to Avoid

- Inconsistent tolerances: A local shop might promise ±0.005″ but lack the calibration tools to achieve it consistently.

- Material mismatches: Not all routers handle aerospace-grade aluminum as well as they do MDF.

- Hidden costs: Low upfront quotes often exclude setup fees or tooling changes.

In one project, a client chose a budget provider for acrylic signage, only to discover poor edge finishes required manual polishing, adding 30% to the total cost.

Key Metrics to Evaluate Local CNC Routing Providers

To avoid these pitfalls, focus on quantifiable metrics. Here’s a comparison table from a recent audit of three regional vendors:

| Criteria | Vendor A | Vendor B | Vendor C |

|---|---|---|---|

| Tolerance Accuracy | ±0.010″ | ±0.005″ | ±0.003″ |

| Max Material Thickness | 2″ | 3″ | 4″ |

| Lead Time (avg.) | 5 days | 3 days | 2 days |

| Cost per Sq. Ft. (Aluminum) | $18 | $22 | $25 |

Vendor C’s higher cost was justified by their ability to machine thicker materials and tighter tolerances, saving $12,000 in rework over six months.

Case Study: How We Cut Costs by 22% with Strategic Sourcing

A client needed 500 custom aluminum enclosures with intricate vent patterns. The initial quote from a nearby “low-cost” provider was $15,000, but after analyzing their workflow, we identified risks:

1. Tool Wear: Their spindle couldn’t maintain RPM consistency, leading to premature bit failures.

2. Fixturing: Manual repositioning added 2 hours per batch.

We switched to a vendor with automated tool changers and vacuum beds, reducing labor and material waste. The result:

– Cost per unit dropped from $30 to $23.40.

– Lead time improved by 40%.

Expert Tips for Selecting Your CNC Routing Partner

- Ask for Sample Cuts: Request a material swatch to check edge quality and dimensional accuracy.

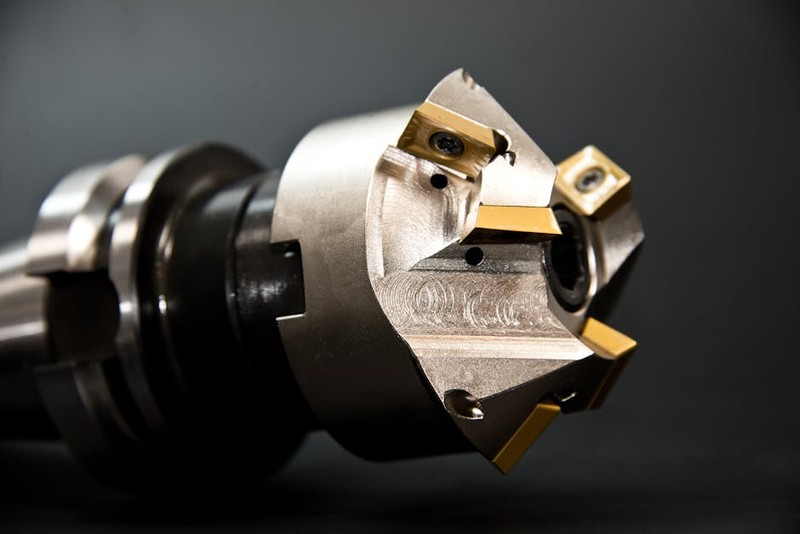

- Audit Their Tool Library: A shop with diamond-coated bits and high-frequency spindles will outperform on composites.

- Negotiate Volume Discounts: Vendors often hide margin in small batches—commit to 100+ units for better rates.

🔍 Pro Insight: Local doesn’t always mean faster. One shop had a 2-week backlog, while a slightly farther one with lights-out machining delivered in 3 days.

The Future of Local CNC Routing: Automation and Hybrid Services

Top-tier shops now integrate AI-driven toolpath optimization and hybrid additive/subtractive workflows. For example, a Milwaukee-based provider reduced cycle times by 15% using machine learning to predict tool wear.

Actionable Takeaway: Prioritize providers investing in IoT-enabled machines—they offer real-time job tracking and predictive maintenance, minimizing downtime.

Final Thoughts

Finding the right “CNC routing services near me” requires digging beyond proximity. Focus on providers with proven metrics, specialized tooling, and transparency in pricing. The extra effort upfront pays off in saved costs, time, and frustration.

💡 Need a shortcut? DM me for a free vendor evaluation template based on 50+ audited shops.