Custom Metal & Plastic Parts | Fast Turnaround & Competitive Pricing

Global Precision CNC Machining

Specializing in aerospace, automotive, and industrial sectors with strict tolerances (±0.005mm). Export-ready solutions for EU/NA markets.

✓ ISO-Certified Quality | ✓ 48H Quote Response

✓ Prototype to Bulk Production | ✓ 15+ Years Expertise

Email: leo@dgflexprecision.com

Precision CNC Machining Services

Delivering high-quality, cost-effective, and fast CNC machining solutions to meet the unique demands of your industry.

- Precision Parts

- Fast Delivery

- Competitive Pricing

- Custom Solutions

- Expert Support

- High-Quality Standards

- Efficient Processes

- On-Time Guarantee

Our client industries

AEROSPACE

For the aviation sector, we deliver specialized CNC machining, crafting vital components like fasteners, connectors, screws, shafts—including those with eccentric hollow designs—pins, and an array of other precision-engineered parts. Our approach combines advanced CNC machining centers with sophisticated turn-mill complex lathe techniques, ensuring each piece meets the stringent quality and reliability demands of aerospace applications.

AUTOMOBILE

We specialize in the precise CNC turning and milling of essential automotive components, including hydraulic and brass valves, valve housings, pipe joints, and sensor metal shells, all critical for car engines and VVT/OCV systems. Our expertise allows us to confidently machine intricate automotive parts, meeting the exacting standards of our global clientele

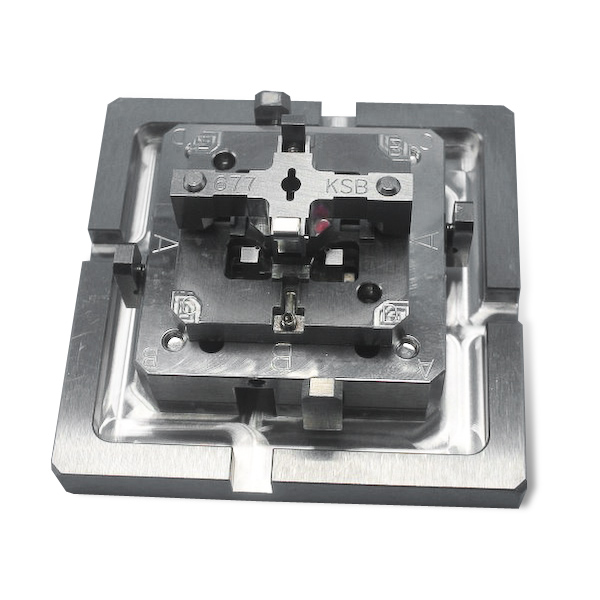

ELECTRONICS

We are dedicated to the production of high-grade CNC machined electronic parts, ensuring unparalleled dimensional precision. Our ISO-accredited facilities excel in crafting intricate components, consistently achieving tight tolerances as fine as ±0.005mm (±0.0002″)

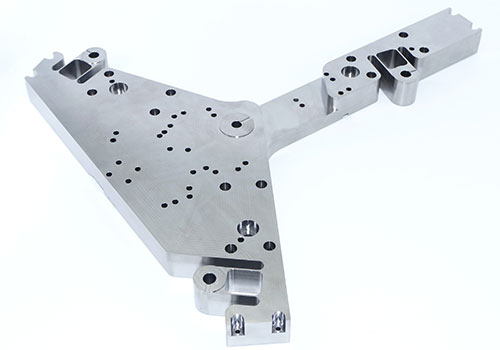

MECHANICAL

For those seeking tailored solutions in CNC machining, turning, and milling, we offer specialized production of custom machinery components. From initial rapid prototypes to large-scale manufacturing, our expertise ensures the creation of precision non-standard parts. We excel in handling intricate geometries with tolerances as tight as ±0.01mm, employing multi-axis machining and a variety of surface treatments, including anodizing, plating, and powder coating. Our services are particularly suited for the automotive, aerospace, and industrial equipment sectors, where AS9100-compliant manufacturing is essential.

MEDICAL AND DENTAL

As a trusted partner in the medical and dental fields, we specialize in the precision CNC manufacturing of critical components. Our ISO 13485-certified facilities are adept at producing a range of items, including surgical instruments, implant components, and parts for diagnostic devices. We utilize materials such as USP Class VI plastics and medical-grade alloys like 316L stainless steel and titanium, ensuring biocompatibility and durability. Offering full traceability and cleanroom machining options, we meet the stringent FDA compliance standards required for dental implants, prosthetics, and pharmaceutical machinery components

MILITARY&DENFENCE

For the defense sector, we deliver mission-critical components via precision CNC machining, adhering to ITAR compliance for aerospace defense systems, armored vehicles, and tactical gear. Our manufacturing processes are MIL-SPEC certified, with inspections traceable to NIST standards. We specialize in machining hardened steel up to 65 HRC, producing EMI/RFI shielding components, and crafting ballistic-resistant alloy parts for NATO-standard applications.

Why Choose Our CNC Machining Services?

R&D Capability

Engineering support in the Research & Development and scientific industry, CNC Machining drawing design, Prototype and batch production, Reliable delivery performance, Exceptional quality standards, all these guarantee our Reliable CNC Machining Services for worldwide clients!

Turning capacity

Our CNC turning capacity is Ø1-20 x 1500mm, Tolerance +/-0.002 and our CNC Turning services is frequently requested for the certain category of CNC parts in various industries. High-tech CNC turning machines & CNC Turning Programming can meet customers’ specific needs for the turning parts.

Production Capability

For further processing of blanks and more complex work pieces, our 3/4/5-spindle CNC lathe machines, high-precision turning-milling centers and centerless grinding machines at our disposal to manufacture the CNC Turning parts in accordance with the requirements.

OEM Capability

All CNC Parts manufacturing is performed solely based on your drawings by means of turning processes. Motor shaft, pins, screw, fastener, knurled, connector, and CNC parts meeting your specifications are manufactured by efficient 3/4/5-spindle or CNC Lathe Services, depending on the production quantity

Quality Control

We ensure the highest quality by using only the highest quality raw materials and subjecting all our CNC machining parts and products to a rigorous Quality Control System. The quality control of our large-scale production process totally confirmed to ISO9001:2015 standards.

Surface Treatment And Finishing

Many CNC work pieces require additional finishing, such as heat treatment, galvanic coatings or various colors anodizing, work that we outsource to our long-standing partner companies which have rich experience and superb technology in plating various Non-Standard CNC machined/turned parts

CNC machining milling

Precision CNC Milling Services – High-Quality Machining Solutions

CNC machining turning

Precision CNC Turning Solutions – Expert Machining for Custom Parts and Complex Geometries

sheet metal fabrication

Precision Sheet Metal Fabrication – Custom Solutions for Complex Designs and High-Quality Manufacturing

Rapid prototyping

Rapid Prototyping Services – Fast, High-Precision Prototypes for Innovative Designs

5 Axis Machining

Advanced 5-Axis Machining Services – Precision Manufacturing for Complex Geometries

Swiss Machining

Precision Swiss Machining Services – High-Accuracy Parts for Complex, Tight-Tolerance Applications

About us

At FLEXPRECISION, we are dedicated to providing world-class precision machining solutions tailored to meet the unique needs of our global clients. Specializing in CNC machining, 5-axis machining, Swiss machining, and sheet metal fabrication, we deliver high-quality, reliable parts for industries ranging from aerospace and automotive to medical devices and electronics.

With cutting-edge equipment and a team of highly skilled engineers, we take pride in our ability to handle complex geometries, tight tolerances, and large-scale production runs. Whether you require rapid prototyping or full-scale manufacturing, FLEXPRECISION is committed to delivering exceptional precision, fast turnaround times, and cost-effective solutions.

What truly sets FLEXPRECISION apart is our unwavering focus on customer satisfaction. We go beyond simply meeting requirements; we aim to build lasting partnerships by offering personalized services, clear communication, and an unmatched level of responsiveness. From prototype to production, we ensure the highest standards of quality at every stage of the process.

In today’s competitive global market, precision, reliability, and efficiency are key. At FLEXPRECISION, we combine advanced technology with expert craftsmanship to deliver machining solutions that elevate your business.

Choose FLEXPRECISION for machining excellence that makes a difference.

Recent Posts

Frequently Asked Questions

What types of CNC machining services do you offer?

We offer a variety of CNC machining services, including CNC turning, CNC milling, CNC drilling, and CNC grinding. We also specialize in precision machining for metals, plastics, and other materials. Our equipment can handle custom, high-precision parts tailored to your specific requirements

What is the typical delivery time for CNC machining orders?

The delivery time for CNC machining depends on the complexity of the parts and the order quantity. Typically, standard orders are completed within 7-14 business days. For larger or more complex projects, the delivery time may be longer. We strive to meet all deadlines and will notify you of any potential delays in advance..

What materials can you machine?

We are capable of machining a wide range of materials, including stainless steel, aluminum, titanium, brass, copper, and various plastics (such as nylon, PTFE, and PVC). If you have a specific material requirement, please contact us to confirm whether it is suitable for our machining capabilities.

Do you offer international shipping?

Yes, we provide international shipping to most countries. Once your order is ready, we will work with you to arrange shipping based on your preference, whether by air, sea, or express delivery. We ensure timely and safe delivery of your goods.

How do you handle urgent or expedited orders?

We understand the importance of meeting deadlines. For urgent orders, please contact our customer service team directly, and we will prioritize your project. We will assess the feasibility of completing the order within your desired time frame and work with you to ensure prompt delivery.

How can I request a quote for my CNC machining project?

To receive a quote, please provide the specifications of your project, including detailed drawings, material requirements, and quantities. You can email the relevant CAD files or drawings directly to us. Once we receive your information, we will review the specifications and provide you with a competitive quote.

Do you handle custom or small batch orders?

Yes, we specialize in both large-scale production and small batch orders. Whether you need prototype parts or limited-run production, our team can accommodate your needs with flexibility and precision.

How do you ensure the quality of CNC machined parts?

We use state-of-the-art CNC machines and maintain a rigorous quality control process to ensure that each part meets the required tolerances. Every part undergoes thorough inspection at various stages of production, including post-processing and final checks. We also offer additional services like surface finishing and coating to meet your specific needs

What industries do your CNC machining services cater to?

Our CNC machining services cater to a wide range of industries, including automotive, aerospace, medical devices, electronics, robotics, consumer goods, and more. We understand the specific requirements of various sectors and provide high-quality parts that meet industry standards.

What is the minimum order quantity (MOQ) for CNC machining?

We do not have a strict minimum order quantity (MOQ). We accommodate both small and large orders, making it ideal for customers requiring low-volume production or large-scale manufacturing. Please contact us with your project details, and we will discuss the best solution for your needs.